API Schmidt Bretten manufactures plate heat exchangers for the cooling of bearings, lube oils and rotor blades of diesel or gas motors and steam and gas turbines. Furthermore API Schmidt-Bretten provides big central cooling heat exchangers.

Headquartered in Bretten, Germany, and with a history of more than 130 years, API Schmidt-Bretten is at the forefront of advances in heat transfer technologies.

API’s products are available in standard and customised versions and are used in a wide range of industries, including chemical processing and power generation.

API’s product range for the power market includes:

- SIGMA: gasketed plate heat exchangers

- SIGMATWIN: gasketed double-wall plate heat exchangers

- SIGMADUAL: semi-welded plate heat exchangers

- SIGMAWIG: all-welded compact plate heat exchangers

- SIGMASHELL: all-welded plate and shell heat exchangers

- BASCO: customised and TEMA type shell and tube heat exchangers

Heat exchangers, evaporators and process heating

API Schmidt-Bretten employs approximately 160 people and works with original equipment manufacturers (OEMs), EPCs, and end-users. API has manufacturing bases in New York, US, Germany and China, with sales support worldwide.

With improvements in heat transfer technology, plate heat exchangers can be used for a wide range of applications, including:

- Evaporation of working fluids

- Condensation of working fluids

- Extraction of heat

- Raw water heater

- Re-cooling of cooling circuits

- Cooling of lube oil for gas turbine, steam turbine, and wind turbine applications

- Cooling of motor cooling water

- Gland steam condensing

- Surface condensing

- Process heating and cooling

- Power plant central cooling

- Compressor cooling

- Atomising air cooling

- Feed water heating

- Kalina process

Gasketed plate heat exchangers

A large amount of cooling water, mostly river or seawater, is used in stationary power plants.

API manufactures plate heat exchangers that have up to 20in (DN500) port holes and plate pressing depths of 4mm. These are used for the requested high-volume flows.

To reduce fouling coming from sea or riverwater, gasketed plate heat exchangers can be opened for cleaning and inspection.

Gasketed and semiwelded plate heat exchangers for geothermal power plants

For geothermal power plants that use the Kalina system, API has designated SIGMA gasketed and semiwelded plate heat exchangers.

These are manufactured using the highest-grade materials, such as titanium, to cope with the corrosive water produced in geothermics, which is pumped from deep rock formations.

When used in geothermics, the heat exchanger also has to be openable for cleaning.

Heat exchangers for further applications

Gasketed plate heat exchangers are exceptionally suited for use in the main transfer stations of district heating networks. Using API’s high performance plates, a NTU-value up to ten can be reached.

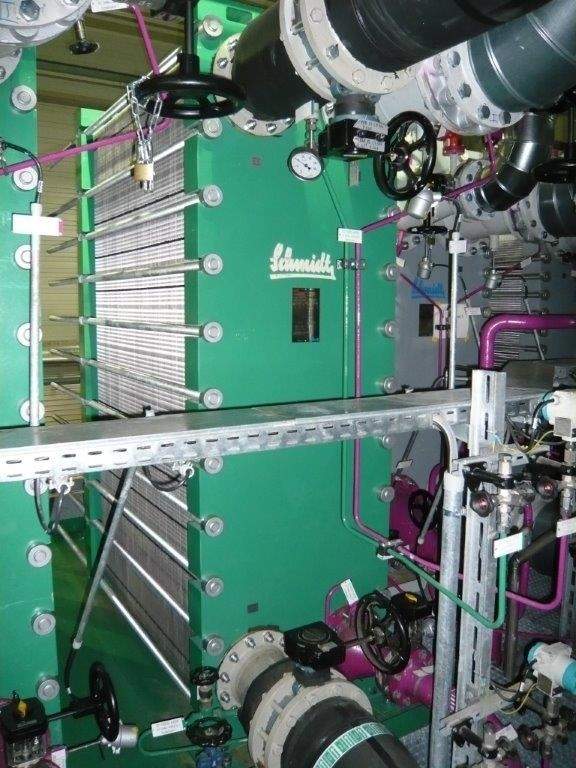

Furthermore, API products cool the lube oil from turbines and generators, with plate heat exchangers used when fresh water or seawater is available.

API can meet unique customer requirements, including oil flushing. Heat exchangers can be packaged in a standardised skid solution with transfer valves and piping (see picture: twin-loop oil coolers).